Still think the jumpy fuel pressure is a cause or symptom.

So you didn't give all the info.

And there is no such a thing as analysis paralysis. Unless you make no changes. It just sounds cool and a pressuring statement.

From another forum:

"Replaced the coil and absolutely no difference. Also put on the injector 3 shield and no difference. I notice it begins right after the vehicle warms up and goes into open loop. Also, I notice that the injector 3 doesn't click as strong as the rest (by placing my finger over each injector). "

"Thank you for the reply! It's exactly as you say, when I clear the code, the jeep behaves better for a while until it throws the code again. Although I put the heat shield on and it is not making any difference. Was wondering what else I can try to make this misfire gremlin go away."

So when you clear the codes it runs fine for a while? Then it is a sensor.

And it only happens after warmup.

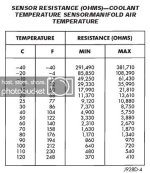

Try measuring the temp sending unit resistance from cold as the engine heats. It should be steady resistance change.

View attachment 23620

Regards,

JPNinPA

Sent using TapTalk